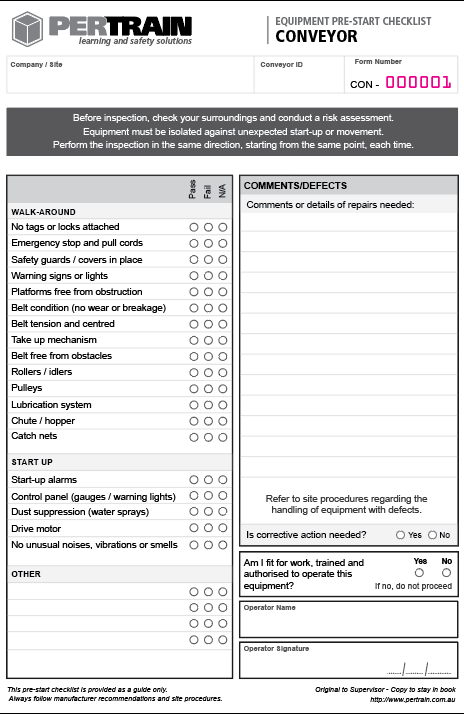

Conveyor Pre-Start Checklist Books

Our Conveyor Pre-Start Checklist Book is designed by industry professionals to assist machinery owners and operators in meeting their obligations while promoting a safe working environment.

Purpose of a Conveyor Pre-start Book

- Identify hazards before operation.

- Ensure safety compliance with site procedures and WHS regulations.

- Record inspections for traceability and accountability.

- Minimise downtime by detecting issues early.

- Protect workers from mechanical failures or unexpected hazards.

Typical Items in a Conveyor Pre-start Checklist

-

General Condition

- Check for structural damage or signs of wear.

- Inspect guarding to ensure it is in place.

- Look for loose or missing bolts.

-

Belt & Rollers

- Inspect belt alignment for tracking issues.

- Check belt tension to prevent slippage.

- Look for wear, fraying, or damage to the belt.

- Ensure rollers and idlers are free from debris and rotate properly.

-

Drive & Motor System

- Check motor and gearbox for leaks or unusual noises.

- Inspect drive chains and couplings for wear.

- Ensure brakes and emergency stops are functional.

-

Safety & Emergency Systems

- Test emergency stop buttons and pull cords.

- Confirm the functionality of warning alarms and lights.

- Ensure fire extinguishers are available (if required).

-

Housekeeping & Environment

- Check for spillage or obstructions around the conveyor.

- Ensure proper dust control measures are in place.

- Verify that walkways and access areas are clear.

Who Uses a Conveyor Pre-start Book?

- Conveyor Operators – Required to complete prestart checks before each shift.

- Supervisors & Safety Officers – Review logs to ensure compliance.

- Maintenance Teams – Use records to schedule servicing and repairs.

Why is it Important?

- Prevents breakdowns and reduces costly repairs.

- Improves safety by identifying hazards before operation.

- Meets workplace and regulatory requirements (e.g., Australian WHS laws).

- Provides a legal record of equipment inspections in case of an incident.