Glass Crusher Pre-start Checklist

Our Glass Crusher Pre-Start Checklist Book is designed by industry professionals to assist machinery owners and operators in meeting their obligations while promoting a safe working environment.

Purpose of a Glass Crusher Prestart Book

- Identifies mechanical, electrical, or safety issues before operation.

- Ensures compliance with workplace safety regulations.

- Helps prevent accidents, machine breakdowns, and costly repairs.

- Provides a record of inspections for audits and maintenance tracking.

- Supports preventative maintenance by logging defects and servicing.

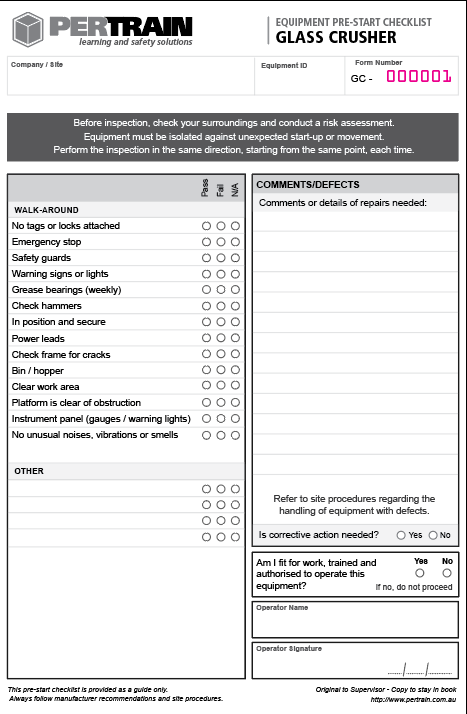

What’s Included in a Glass Crusher Prestart Book?

-

Machine Details:

- Make, model, and serial number.

- Fleet/plant ID and location.

- Operator name and date.

-

Prestart Inspection Checklist:

- Power Supply & Electrical System: Check wiring, emergency stop function, motor operation.

- Hydraulics (if applicable): Inspect for leaks, proper pressure levels, and hose integrity.

- Belts, Chains & Drive Components: Check for wear, tension, and alignment.

- Crusher Blades & Hammers: Inspect for wear, damage, or blockages.

- Feed Hopper & Conveyor System: Ensure no obstructions, proper alignment, and smooth operation.

- Dust Extraction/Ventilation System (if applicable): Check for proper function.

- Safety Guards & Interlocks: Confirm guards are secure and all safety interlocks are functioning.

- Fire Safety Equipment: Ensure fire extinguisher is present and operational.

- Operational Test: Start the machine and check for unusual noises, vibrations, or performance issues.

-

Defect Reporting Section:

- Space for operators to report faults or irregularities.

- Supervisor acknowledgment and actions taken.

-

Maintenance Log:

- Record of completed repairs or servicing.

-

Operator Sign-Off:

- Confirmation that the prestart check was completed.

- Acknowledgment of any identified faults.

Who Uses a Glass Crusher Prestart Book?

- Operators & Site Workers – Complete prestart checks before use.

- Supervisors & Safety Officers – Review logs for compliance.

- Maintenance Teams – Use records to schedule servicing and repairs.

Why is it Important?

- Ensures the glass crusher is safe and functional before operation.

- Reduces workplace accidents and equipment failures.

- Ensures compliance with WHS and site safety regulations.

- Provides a legal record of inspections for audits and safety reviews.