Water Blaster / Pressure Cleaner Pre-start Checklist Books

Our Water Blaster / Pressure Cleaner Pre-Start Checklist Book is designed by industry professionals to assist machinery owners and operators in meeting their obligations while promoting a safe working environment.

Purpose of a Pressure Cleaner Prestart Book

- Identifies mechanical, hydraulic, or safety issues before operation.

- Ensures compliance with site safety and WHS regulations.

- Helps prevent accidents, breakdowns, and costly repairs.

- Provides a record of inspections for audits and maintenance tracking.

- Supports preventative maintenance by logging defects and servicing.

What’s Included in a Pressure Cleaner Prestart Book?

-

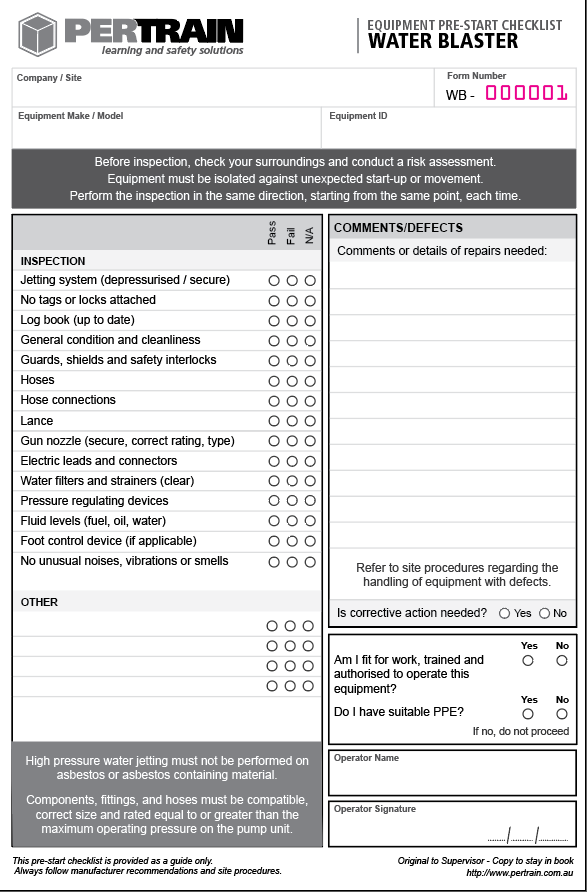

Pressure Cleaner Details:

- Make, model, and serial number.

- Fleet/plant ID and location.

- Operator name and date.

-

Prestart Inspection Checklist:

- Fluids & Fuel Levels: Check fuel (for petrol/diesel models), engine oil, and water supply.

- Battery & Electrical System (if applicable): Battery charge, wiring, power supply connections.

- Hoses & Connections: Inspect for leaks, cracks, kinks, or blockages.

- Nozzles & Spray Gun: Check for clogs, wear, and secure fittings.

- Pressure & Flow Rate: Ensure correct pressure output and smooth flow.

- Pump & Motor: Check for unusual noises, overheating, leaks, and proper mounting.

- Frame & Wheels (if mobile): Check for stability, damage, and proper movement.

- Emergency Stop & Safety Features: Ensure shut-off valves, safety latches, and emergency stop function correctly.

- Operational Check: Test start, confirm pressure stability, and observe for leaks or unusual vibrations.

-

Defect Reporting Section:

- Space for operators to report faults or irregularities.

- Supervisor acknowledgment and actions taken.

-

Maintenance Log:

- Record of completed repairs or servicing.

-

Operator Sign-Off:

- Confirmation that the prestart check was completed.

- Acknowledgment of any identified faults.

Who Uses a Pressure Cleaner Prestart Book?

- Operators & Site Workers – Complete prestart checks before use.

- Supervisors & Safety Officers – Review logs for compliance.

- Maintenance Teams – Use records to schedule servicing and repairs.

Why is it Important?

- Ensures the pressure cleaner is safe and functional before operation.

- Reduces workplace accidents and breakdowns.

- Ensures compliance with WHS and site safety regulations.

- Provides a legal record of inspections for audits and safety reviews.

Equipment Owners have a legal requirement to provide equipment that’s fit–for–purpose and safe to use.

Equipment Operators have an obligation to ensure equipment is safe to use before using it.

For larger orders we offer full customisation (Add a logo, change colours or alter the checksheets). Call us for a price.